VR Modeling of the Centennial Challenge NEST proposal

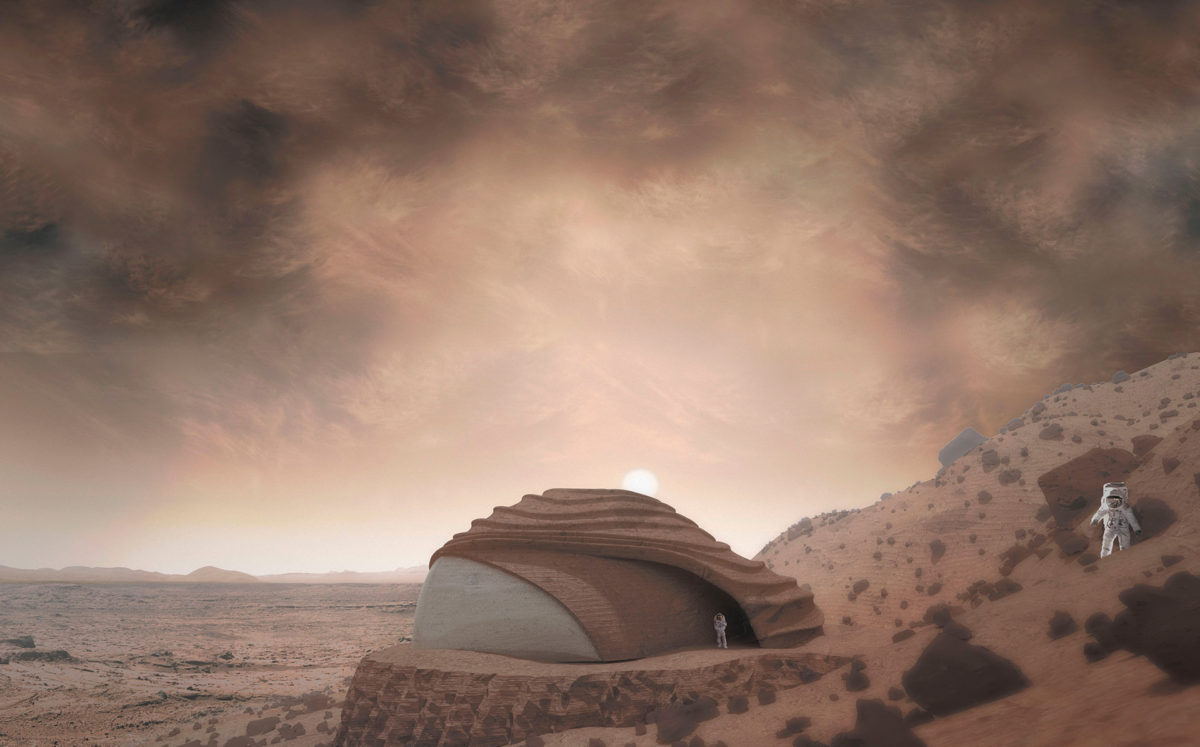

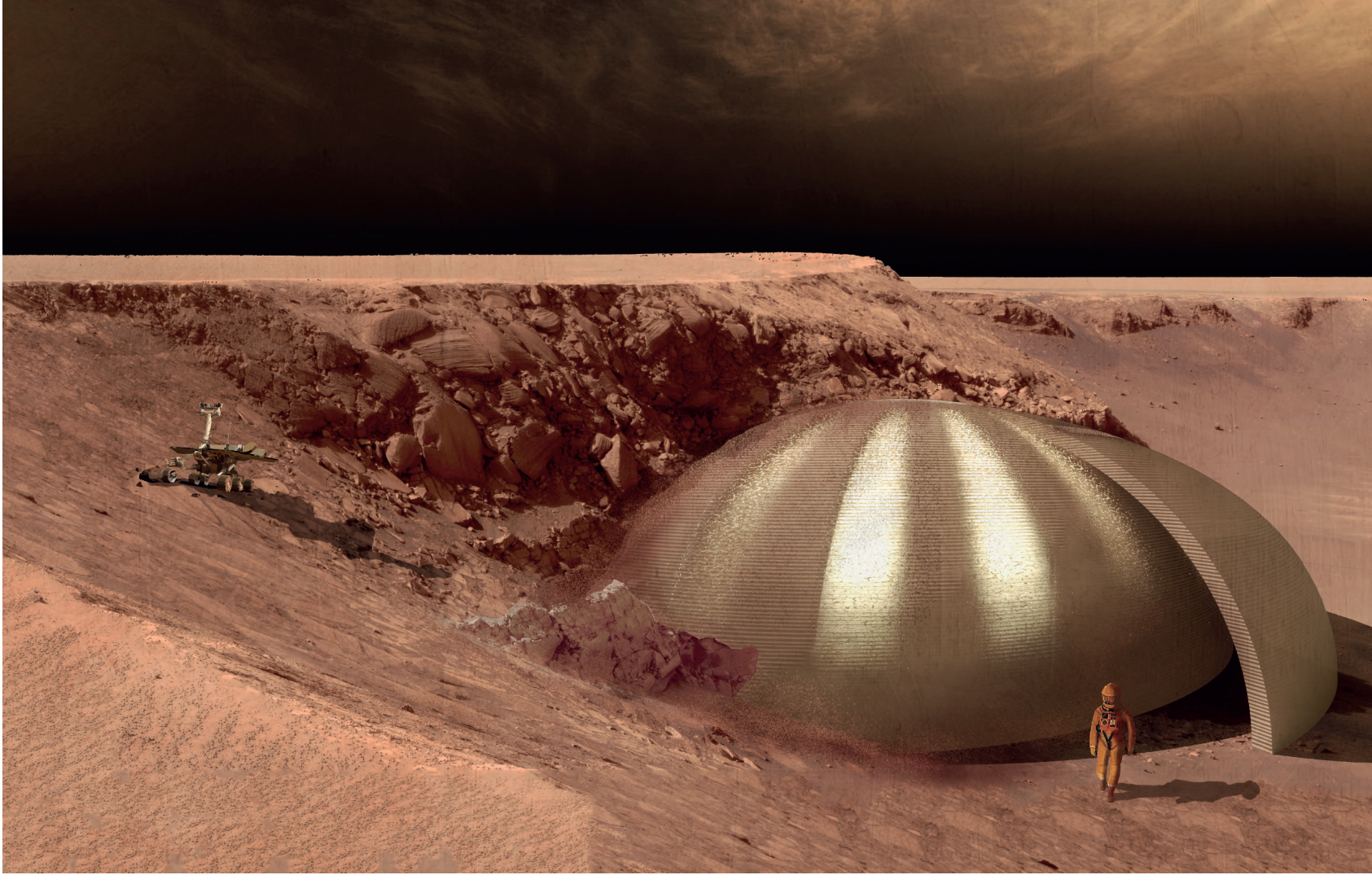

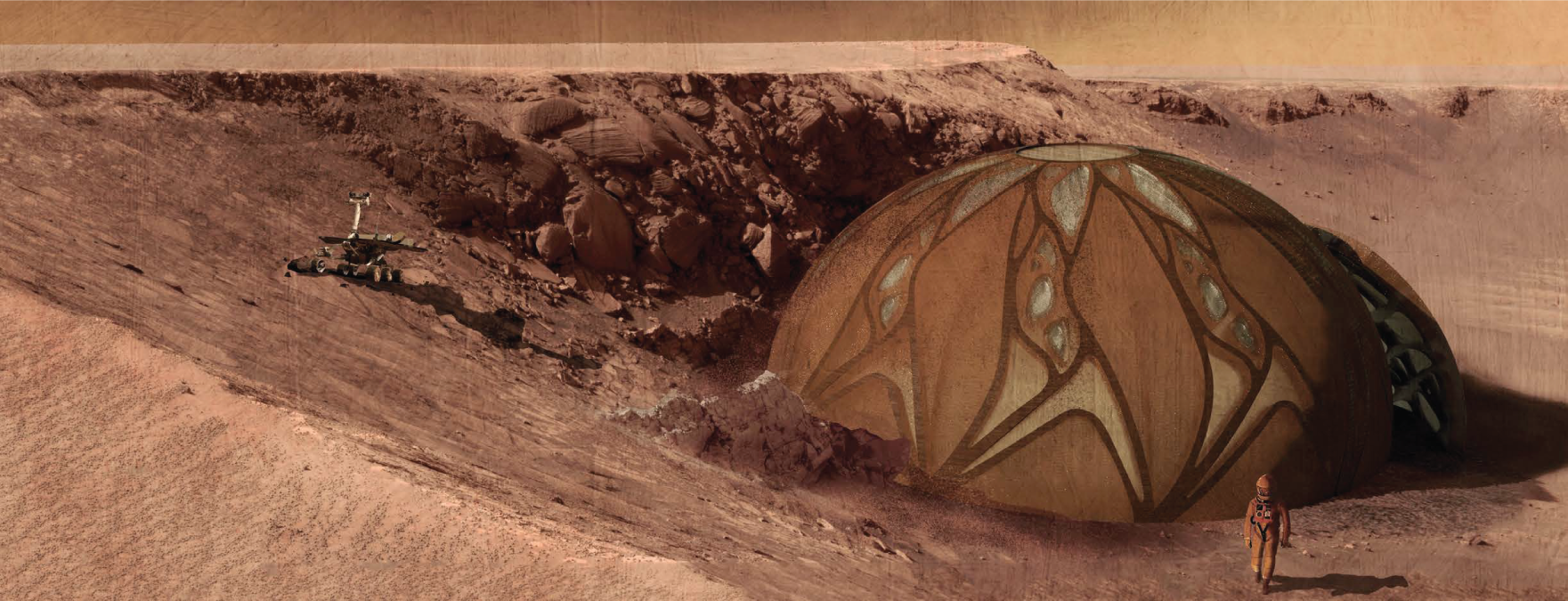

The NEST project consisted of a 3D-printed settlement for Mars exploration, built from local materials and capable of accommodating four inhabitants. As part of the Nasa 3DPH Challenge, this project was defined by the extreme conditions posed by the Martian environment: a low gravity (0.3 G), lack of breathable air and surface liquid water, as well as high levels of harmful solar and cosmic radiation (Harbaugh, 2015).

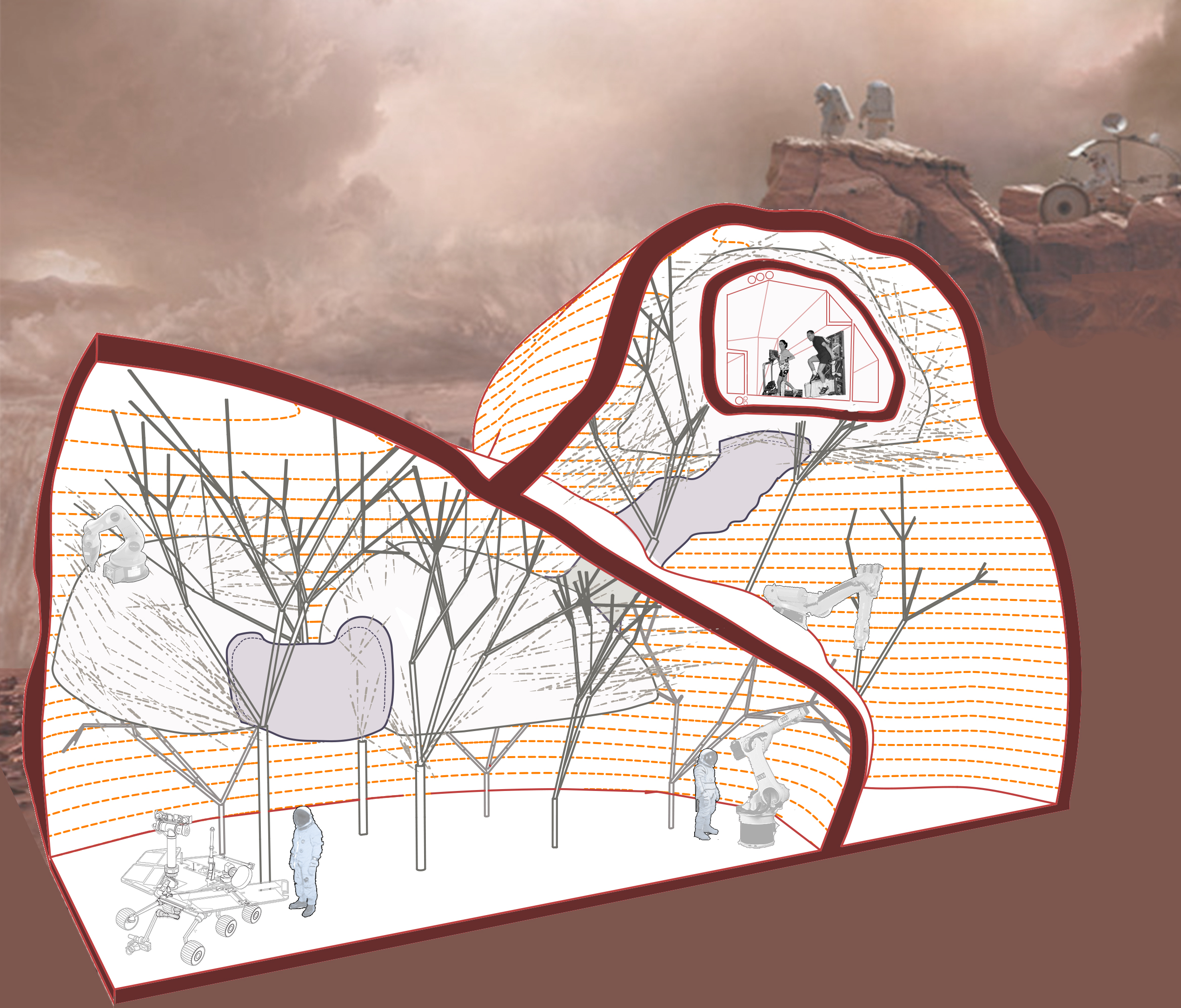

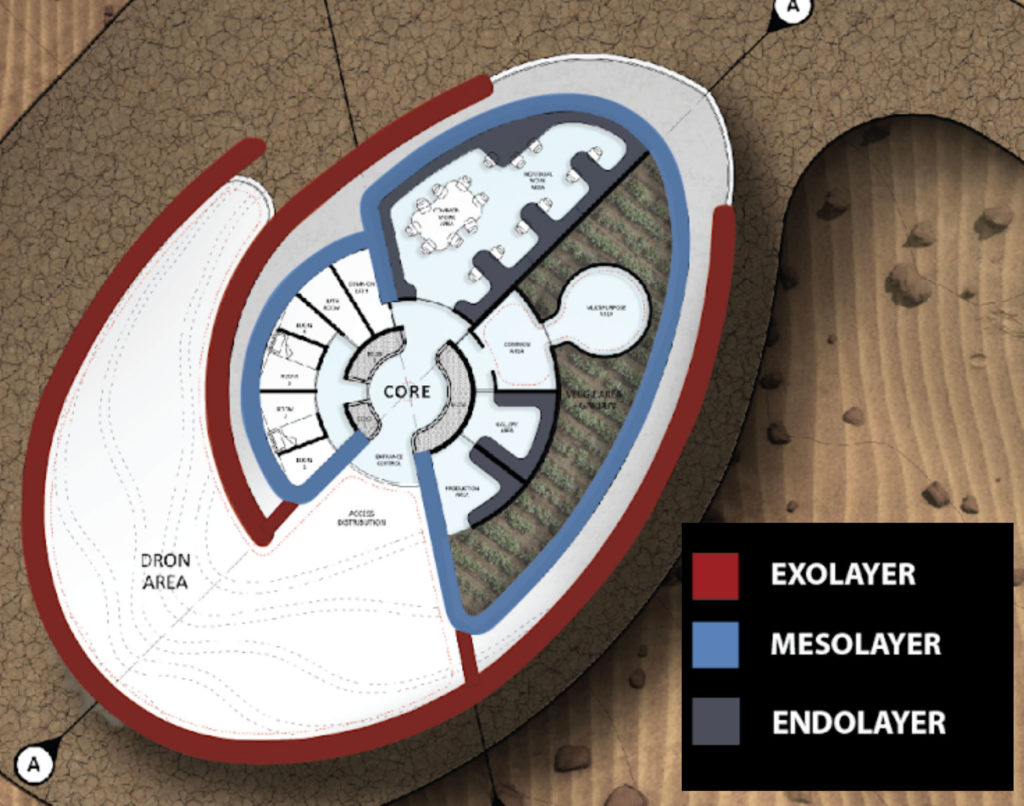

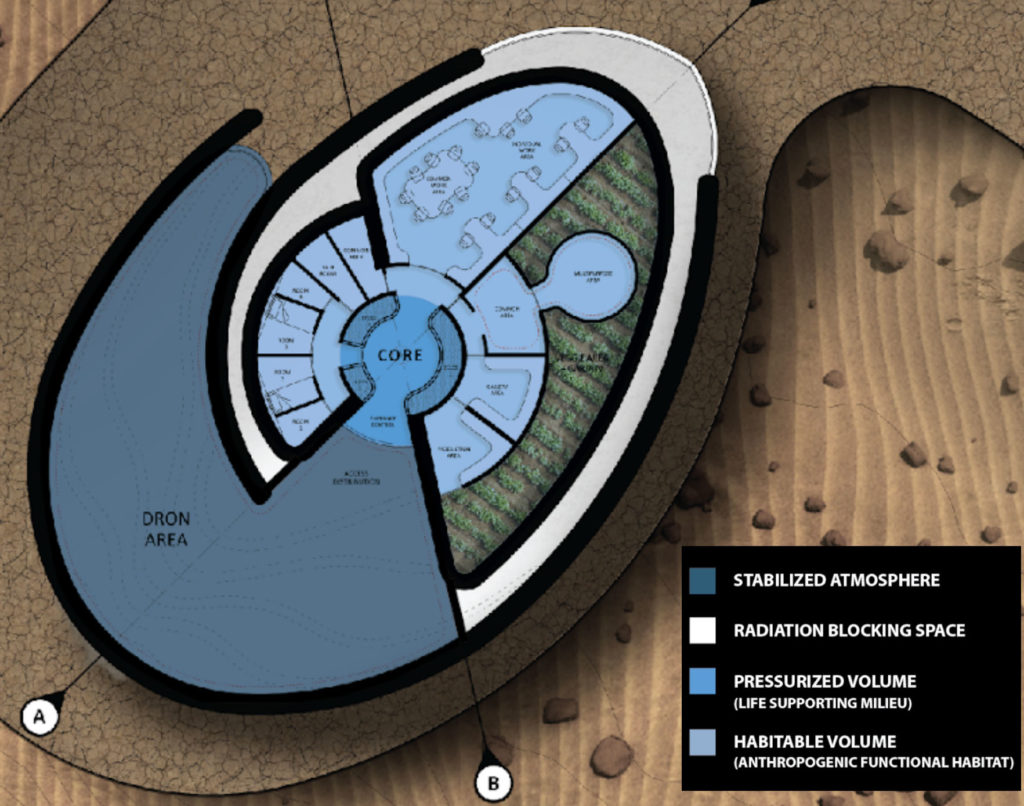

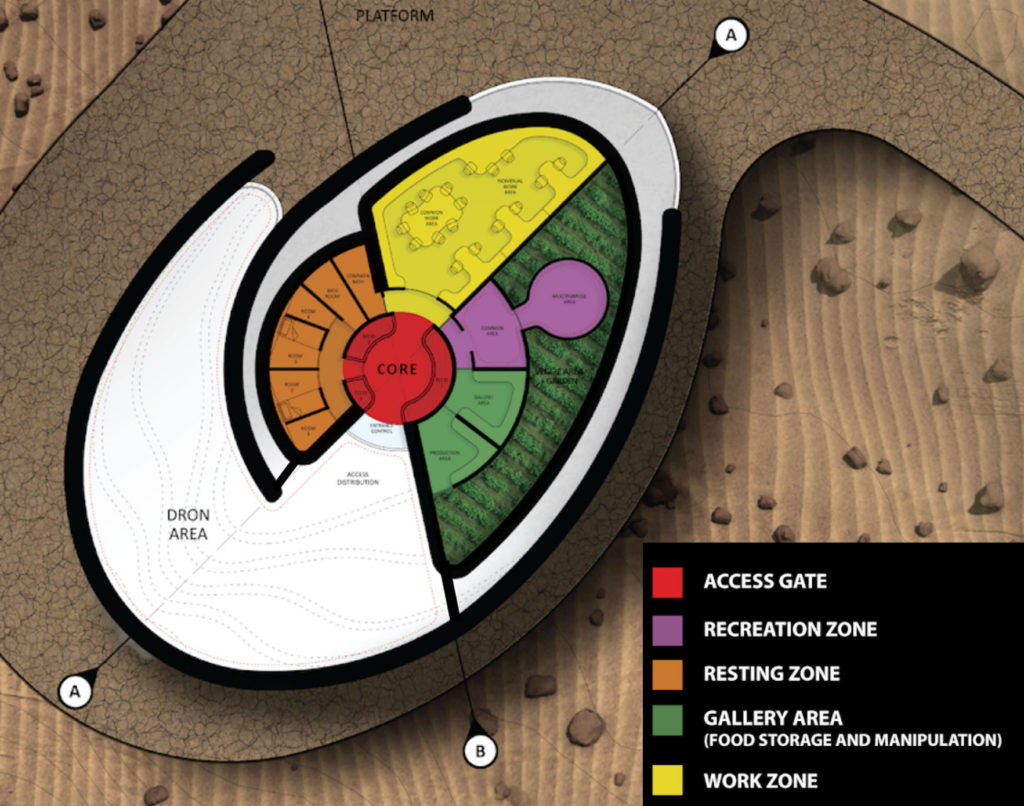

The architectural concept is a Nested Environment-Settlement Technology (NEST). This means designing a series of nested concentric habitable volumes and the 3D print of safety structural layers in between (figure 1). This allowed us to add barriers between the exterior Martian environment and exterior to better control environmental hazards and provide protection for the occupants and machinery operations. Moreover, having many volumes made possible to organize the habitat functions and zones for activities (Figure 2). Specifically, the concept included an external protected volume, as a protected zone for drones and rovers from dust and other environmental hazards; a pressurized volume for the growth garden and in between spaces; and a habitable net volume for the astronauts’ dwellings (figure 3)

These zones are defined by three separate different layers, fabricated by distinct 3d print materials. These were defined as an Exolayer, for the outer layer printed with mud; a Mesolayer, as the in between layer printed with a silicate-glass 3d print approach; and an Endolayer, thought to be printed with PLA and other materials for the habitable and functional membrane of the building.